how to field test wood for hardness|complete janka wood hardness scale : specialty store The Janka hardness test (English: / ˈ dʒ æ ŋ k ə /; [1] German:), created by Austrian-born American researcher Gabriel Janka (1864–1932), measures the resistance of a sample of wood to denting and wear. [citation needed] It measures the force required to embed an 11.28-millimeter-diameter (7 ⁄ 16 in) steel ball halfway into a sample of wood.(The diameter was . Resultado da Compre online Amor Próprio, de Marinalva Callegario na Amazon. Frete GRÁTIS em milhares de produtos com o Amazon Prime. Encontre .

{plog:ftitle_list}

WEBSaiba qual é a previsão do tempo para os próximos 15 dias em Feira de Santana - BA. Confira se haverá previsão de chuva para Feira de Santana - BA na Climatempo, o melhor site de meteorologia .

The Janka hardness test measures the amount of force required to embed a 0.444 inch (11.28mm) diameter steel ball into a piece of wood to the depth of half the ball's diameter.The Janka hardness test (English: / ˈ dʒ æ ŋ k ə /; [1] German:), created by Austrian-born American researcher Gabriel Janka (1864–1932), measures the resistance of a sample of wood to denting and wear. [citation needed] It measures the force required to embed an 11.28-millimeter-diameter (7 ⁄ 16 in) steel ball halfway into a sample of wood.(The diameter was .The Janka hardness test is a standard test used to determine the hardness of wood. It measures the force required to embed a small steel ball into the wood to half its diameter. This measurement indicates the wood’s resistance to . Wood hardness tests give you a number, but that doesn’t tell the whole story. Think of it like comparing apples and oranges — a hard wood might be brittle and chip easily, while a softer wood .

A procedure called the Janka hardness test provides the answers, Dale. Using a powerful press and a steel ball with a diameter of .444", technicians measure the force required to sink half the ball diameter into the face grain of a wood sample. The resulting number, expressed in pounds of force, determines the hardness rating of the species.6. Factors Influencing Wood Hardness: Wood hardness is not solely determined by the species; external factors play a role. Examine the influence of growth conditions, age, and specific wood treatments on the hardness of different woods, offering a more nuanced perspective for wood enthusiasts. 7. Balancing Aesthetics and Hardness:

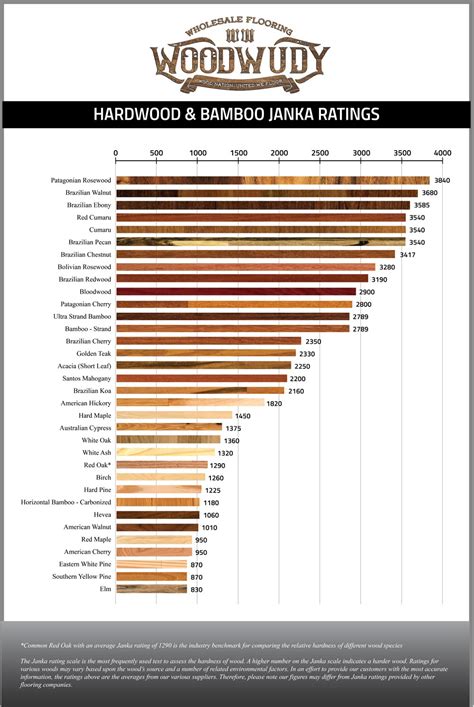

Wood species worldwide number around 10,000 or more. If you do the testing yourself, you might get confused. However, we now have the Janka Wood Chart or Hardness Scale because of the Janka Test. The Janka Hardness Scale evolved from the Brinell Scale—a standardized hardness test designed for the fields of metallurgy and engineering.tests. It can provide reliable hardness measurements even on surfaces with moderate roughness, making it a practical choice for a wide range of materials and surface conditions. Surface Roughness Portable Rockwell hardness testers are available, which allow for on-site or field hardness testing. This is advanta- Let’s dive into the Janka hardness scale so you don’t make the same mistake I did. What Is the Janka Hardness Scale? The Janka scale, simply put, records the density of wood by testing its resistance to denting. The test measures the force required to embed a .444-inch (11.28mm) diameter steel ball halfway into a piece of wood.

Wood hardness testing comes a bit late when a new hardwood floor is installed and it becomes indented by high heel shoes a pebble, furniture legs or other method. A Woman Can Damage Hardwood Faster Than an Elephant! The Physics Handbook ask the question, “What exerts more pressure-per-square inch when walking a 100 lb woman in high heels or a . The Janka rating is the standard grade used throughout the industry, and it can be used to quantify the hardness of the wood as a material. The exact value provided in the wood profile is the amount of pounds-force (lbf) or newtons (N) necessary to embed a steel ball with a diameter of 0.444 inches (11.28 mm) into the wood to a depth equal to half the ball’s diameter.

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .Wood hardness testing I have always been meaning to figure out a simple way to characterize the strength of some of the wood that I use. Looking around on the web, there is the well established Janka hardness test. This test involves pushing a steel sphere of 11.28 millimeters half way into a piece of wood. Doing this requires a specialized . Key Takeaways: Wood hardness and workability are essential considerations when choosing wood for specific applications.; Density, grain pattern, and chemical composition are key factors affecting wood hardness and strength.; Cellulose, hemicellulose, and lignin play crucial roles in determining wood strength at various levels of structure.; Environmental .

Today the Janka hardness test is more or less the standard test for measuring the hardness of wood throughout the world. How Does the Janka Test Work? Janka hardness test: Fair Use. The Janka rating is a number that corresponds to the force required to push a steel ball halfway into the surface of wood. The test uses a steel ball of 11.28 mm (7 . The Mohs hardness scale rates the hardness of minerals based on their ability to scratch softer ones. The Mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch . Understanding the durability ratings of hardwood is crucial when making your selection.One key factor to consider is the Janka hardness rating, which measures a wood species’ resistance to wear and denting.The higher .

This wood hardness list ranks 75 types of wood by their Janka rating. Explore our wood density chart to see which hardwood is the best for your next project! The Janka hardness scale measures the force that’s required to embed a steel ball halfway through a sample of wood. Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the . Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness Testing. Hardness testing is important for a number of different reasons. The hardness of a material can be a critical parameter in its .The Janka Side Hardness test measures the force required to press an 11.28mm (0.444 inch) steel ball to half its diameter cross-grain into a block of wood. This force is recorded in both pounds-force (lbf) and kilo-Newtons (kN). We have found this to be one of the best measures of the ability of wood species to withstand denting and wear. .

The scale was developed as a means for displaying the results of the Janka hardness test. The test uses a 2″ x 2″ x 6″ piece of wood and a 0.444″ steel ball to determine how hard the wood is. The test figures out how many pounds per square inch, or PSI, of force, is needed to push the steel ball halfway into the wood plank.

Find out more about the test, how wood is graded, and how the results can help you decide which wood to purchase. How The Janka Test Works. The Janka hardness test and the system of the rating was created by Gabriel Janka. The Austrian immigrant to the USA worked for the U.S. Department of Agriculture's Forest Products Lab in the early 20th .Mohs hardness kit, containing one specimen of each mineral on the ten-point hardness scale. The Mohs scale (/ m oʊ z / MOHZ) of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to scratch softer material.. The scale was introduced in 1812 by the German geologist and mineralogist .

Also, the indenter should be perpendicular to the test surface. For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from each other. For the Knoop hardness test, the two halves of the long diagonals must .Measuring a wood’s flat or horizontal grain (face) is the most general way to determine its hardness. Although vertical wood grain (edge) is tested, the results are not displayed on the Janka Hardness Scale. The results shown on the Janka Hardness Chart indicate the hardness of a wood’s face, and not its edges (or “side hardness”).The hardness is determined by testing the amount of force necessary to implant a steel ball into a plank of wood. The result is that the hardness, resistance, and durability of the wood are tested using this method. The harder the wood, the more force is required to implant the steel ball. The softer the wood, the less force is necessary.

wood janka chart

Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to .

charpy impact test values for steel

charpy impact test velocity

Resultado da An IP is a unique address of a server on the internet. Similar to how a telephone number allows you to connect to a specific phone on the telecom network, similarly, an IP address allows your computer to connect to a specific server on the internet.

how to field test wood for hardness|complete janka wood hardness scale